MIL-DTL-6070C

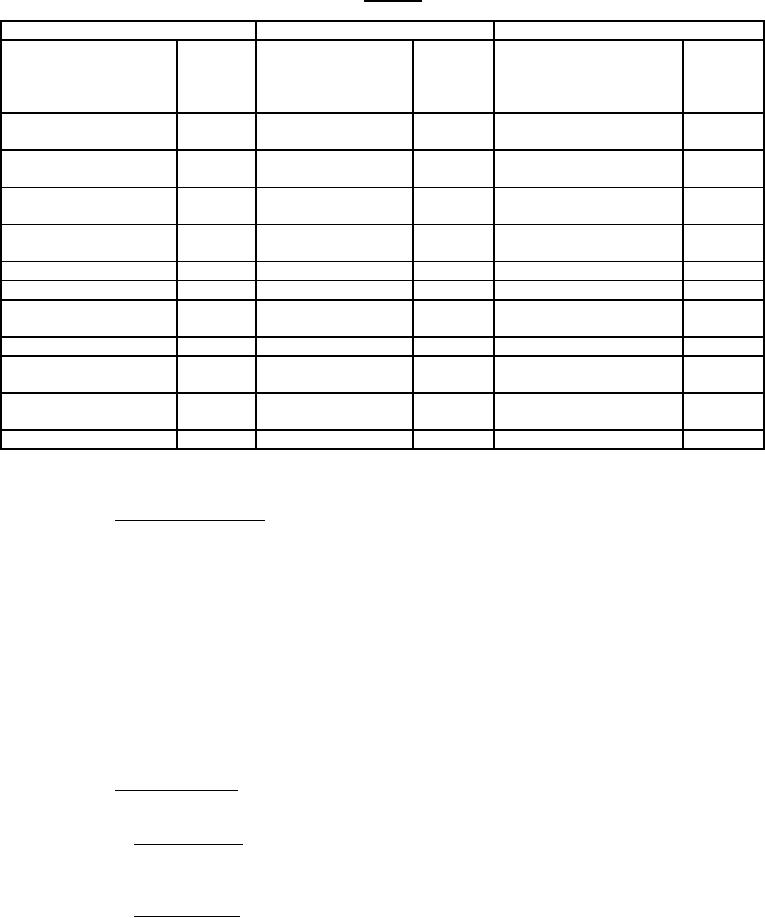

TABLE I

Group I (High Density)

Group II (Medium Density)

Group III (Low Density)

Species

Minimum

Species

Minimum

Species

Minimum

Specific

Specific

Specific

Gravity

Gravity

Gravity

(1)

(1)

(1)

American Beech

0.60

Birch

0.53

Basswood.

0.36

(Alaska and Paper)

Birch (Sweet and Yellow)

0.58

Khaya

0.42

Yellowpoplar.

0.38

(African Mahogany)

Pecan

0.62

Magnolia

0.48

Port Orford White Cedar

0.40

(Southern)

Maple

0.60

Mahogany

0.46

Spruce (Red and Sitka)

0.36

(Hard) .

(Tropical American)

(Quarter Sliced)

Maple, Soft

0.46

Sugar Pine

0.34

Sweetgum

0.48

Noble Fir (Quarter Sliced)

0.36

Water-Tupelo

0.47

Western Hemlock

0.40

(Quarter Sliced)

Black Walnut

0.52

Redwood (Quarter Sliced)

0.38

Douglas Fir #1

0.45

Douglas Fir #2

0.38

(Quarter-Sliced)

(Quarter Sliced)

American Elm

0.50

Ponderosa Pine

0.38

(Quarter Sliced)

(Quarter Sliced)

Sycamore

0.49

Note: (1) Specific gravity based on weight and volume when oven dry.

3.4.2 Permissible open defects. The face ply shall be free of open defects to provide a smooth finish

surface. The inner plies and back may have the same permissible defects as the face, and in addition,

open defects as herein after specified. Permissible defects may appear singly as one type only or as a

combination of more than one type. When more than one type of defect is present, their total limitation,

computed according to the equivalent defects given below, shall not exceed the limit specified for any one

type. When defects other than those specified, or concentration of defects, are encountered, they are

permitted provided their damaging effect is not more critical than those specified herein. The following

shall be regarded with respect to their effect as the equivalent of one 3/8 inch sound knot:

a.

One 3/8 inch knot hole.

b.

One 3/4 inch sound tight burl.

c.

One insect hole 2 inches in length that cuts across the grain 3/8 inch.

d.

One pitch pocket, with the product of length and width equal to 1/4 square inch.

e.

One split 8 inches in length and 1/32 inch in width.

3.4.3 Defects in face plies. Permissible defects in face plies shall not exceed the limitations specified

herein.

3.4.3.1 Sound tight knots. No single Knot shall exceed 3/8 inch in average diameter. The total

number of sound tight knots in face plies shall not be more than six in any 12 inch square, and the sum of

the knot diameters in any 12 inch square shall not exceed 3/4 inch.

3.4.3.2 Sound tight burls. No single burl shall exceed 3/4 inch in average diameter. The total number

of sound tight burls in face plies shall be not more than six in any 12 inch square, and the sum of the

diameters in any 12 inch square shall not exceed 1-1/2 inches.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business