MIL-DTL-6070C

4.5 Tests.

4.5.1 Testing straightness of grain. The slope of the grain requirement in 3.5 shall be determined by

combining the grain direction of two adjacent faces of a square or rectangular piece. When one or more

faces is straight grained, the true slope of the grain is shown on the other face. When there is a slope on

both faces, the true or combined slope is greater than the slope on either face. Slope of grain is shown on

edge-grained faces by summer-wood bands; by the direction in which a free flowing ink or dye spreads;

by the course taken by a narrow strip lifted by a knife point and torn out, or by the Teco or edge slope-

grain Detector. Slope of grain from the edge of the sheet may be readily determined in rotary cut veneer

by tearing the sheet and measuring the slope of the tear.

4.5.2 Mandrel bending tests. The size of the specimen for mandrel bending tests, when required, (see

3.5), shall be one inch across the grain of the veneer and between nine and eleven inches in length. The

ration of the radius of the mandrel to the thickness of the veneer shall be as specified in Table IV. The

specimens shall be cut with the minimum slope of the grain from the edges and shall be oven dry at the

time of the test, the tight side of the veneer shall be outward and the open side against the mandrel. The

specimens shall be bent at the specified radius to a parallel-sided "U" shape without support on the

tension side. Breakage shall consist of fractures extending 1/8 inch or more across the width of the

specimen. Tears along the fiber direction that begin at the edge and extend into the specimen along grain

sloping from the edge shall not be considered breakage. Whether a specimen breaks shall be determined

before removal

from the mandrel. Breakage of more than 20 percent of all the specimens tested shall be considered cause

for rejection of the flitch, crate, or stack.

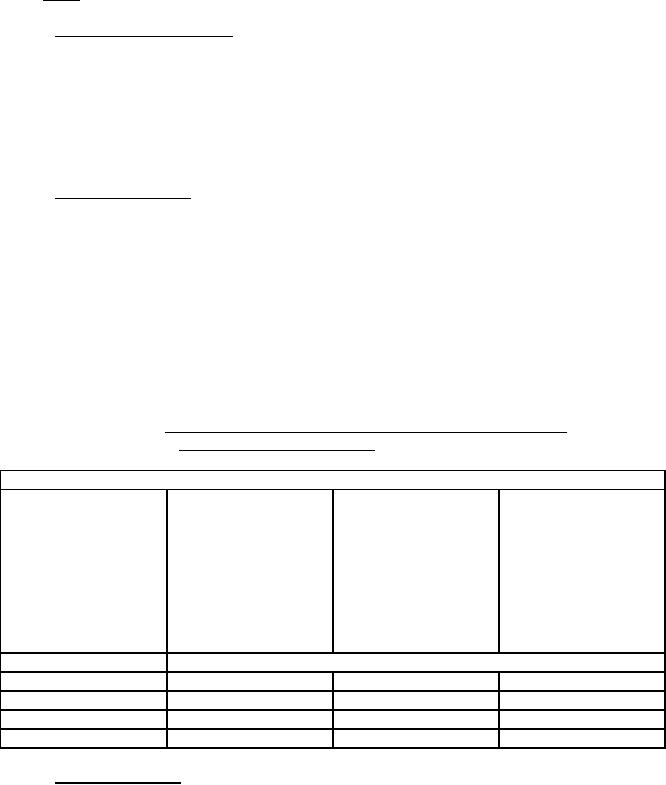

Table IV. Ratio of radius (R) of mandrel to thickness (T) of different species

for use in mandrel bending tests .

Group of Species

Douglas-fir

Magnolia,

Basswood,

Noble Fir

American Elm,

Soft Maple,

Western Hemlock

Sweetgum,

Yellowpoplar,

Spruce, White

Birch,

Water Tupelo,

Red and Sitka

Alaska and Paper Recan

Sycamore,

Thickness

Port Orford

Black Walnut,

Mahogany,

of

White Cedar

Sugar Maple,

Khaya

Veneer

Pine Ponderosa

Yellow Birch,

Pine, Sugar

Beech

Inches

Ratio R/T

0.011 and 0.020

46

34

47

0.030

46

34

57

0.034 to 0.047

50

40

57

0.060

55

50

67

4.5.3 Specific gravity tests. Specific gravity of veneer shall be determined in accordance with ASTM

D2395. The thickness shall be measured to the nearest 0.001 inch. Specimens may be oven dry at time of

test or the weighings may be made at the prevailing moisture contents providing that the proper

corrections are made to convert to oven-dry weight and volume for comparison with the values in Table I.

If the average specific gravity of the specimens selected is below the minimum specified in Table I,

additional specimens, at least 20 from at least 4 additional sheets of veneer or at least 10 from each end of

each bolt or flitch, shall be cut and the specific gravity determined. If the average specific gravity of all

specimens (original specimens plus additional specimens) is below the minimum specified in Table I, the

veneer from that crate, stack, bolt, or flitch shall be rejected. If the average of all determination is above

the minimum but the average specific gravities of individual sheets are below the minimum specified in

Table I, those individual sheets whose average specific gravity is below the minimum shall be rejected.

9

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business